Find the right products for your vehicle

Tap your countries flag to shop or send an inquiry.

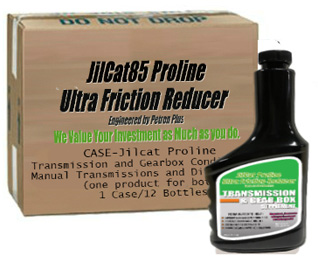

JILCAT Proline™ Patented Hydrocarbon Technology, Ultra Friction Reducer Supplements & Lubricants – Engineered for Aerospace, Tested in Professional Racing and Used by our Military.

Our products remove carbon, corrosion, rust, and sludge buildup through an electrostatic process, while helping prevent additional damage by bringing the metal back to its original state and allowing the return of factory oil pressure.

• 100% Original Patented Technology • Proven Track Record • Tested in Professional Racing – 100% Durable • Eco-friendly Certified by the EPA. • The products do not contain chemicals, dense metal particles, zinc, or mercury. • Auto, Boat, Motorcycle, Semi – Industrial equipment, turbines, ships, and aircraft power-trains • 100% guarantee on products – Weapons Oil also available

Lower Maintenance Costs

Sludge causes more wear/damage to bearings and other metal parts robbing performance and drastically cuts engine lifespan.

Protect Future Wear

Jilcat Products reduce metal wear, reduce component heat, and increase fuel range for superior and enduring performance

Trusted Clients

Dealerships, Consumers, Aerospace, Professional Racing and Military

Patented Technology

Prevent friction and future damage to almost any metal component.

Automotive Drive Line Components

Remove friction lowering the operating temperature, slows component wear, increase power and reduce maintenance.

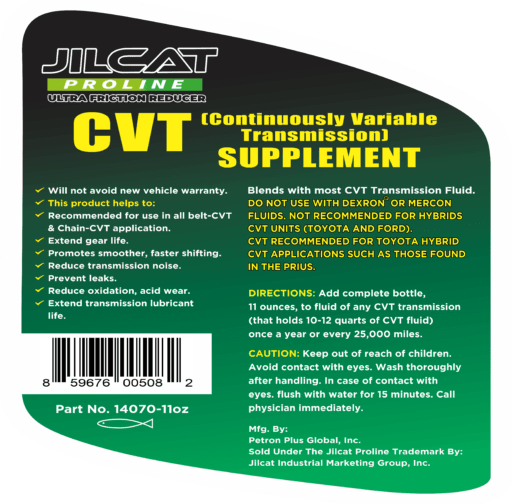

CVT ISSUES

Feeling Vibration or Shutter Problems with your CVT? JilCat addresses these issues immediately, for a fraction of the cost of replacing your engine.

Q & A Regarding Known Issues and Solutions

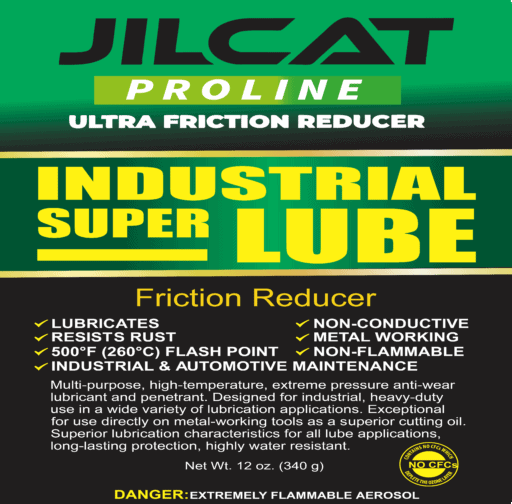

JILCAT Proline Ultra Friction Reducer

- Are you experiencing a vibration and shutter problem with your CVT

- Transmission?Does your 5.3 Chevrolet produce annoying lifter ticking noise?

- Is your HEMI having oil pressure issues, rattling at startup?

- Are you hearing a tick or looking at a Cam Phaser issue in your Ford 5.4 valve

- Is your mechanic quoting you thousands of dollars in transmission or engine repairs?

JILCAT Proline Ultra Friction Reducer goes to work immediately!

Keep the hard- earned money you would have spent on high dollar repairs in your wallet! Not all mechanics do not know everything that is available.

According to research, the costs to overcome friction can account for almost 10% of the Gross National Product (GNP) in various countries.The best-verified lubricant solution can save up to 1% of GNP.

- JILCAT Ultra Friction Reducer and Metal Conditioner – The science behind JilCat is engineered for aerospace, used by our military, and tested in professional racing. What’s more? these patented eco-friendly lubricant products are made in America!

- JILCAT products with Patented Hydrocarbon Technology decrease metal water, reduce component heat, and increase fuel range for superior and enduring performance.

- JILCAT’s friction-reducing additives, supplements and treatments are infused in oils or applicable fluids used for engines, transmissions, CVT’s, and all weapons. They are also utilized in industrial equipment, turbines, ships, and aircraft powertrains.

- The products do not contain chemicals, dense metal particles, zinc, or mercury.

- Jilcat Products will purify the engine by removing carbon, corrosion, rust, and sludge buildup, through an electrostatic process, while helping prevent additional damage by bringing the metal back to its original state, and allowing the return of factory oil pressure.

The application of Jilcat Supplements will eliminate friction which will ultimately reduce operating temperature, slow component wear, and provide an upsurge of power in your engine.

What makes JilCat Proline products different? They are engineered by Petron Plus and Petron Plus along with Petronomics® products are unique.

The waste of resources resulting from high friction and wear were estimated at $194 Billion Dollars by Dr. E. Rabinowicz, of MIT in the United States alone, and well over $5 Billion Dollars by the National Research Council’s Associate Committee on Tribology (the study and application of the principles of friction) in Canada. The potential savings offered by improved lubrication and a better understanding of the science of Tribology (the study and application of the principles of friction) are correspondingly great.

Is it any wonder that the lubrication of machinery never receives much consideration and when a serious problem does occur, most people tend to blame it on the lubricant itself, instead of learning how to recognize the root that caused the problem.

These shortcomings in the understanding of lubricants and lubrication have led many maintenance specialists to make incorrect and costly assumptions about lubricants and their application. Furthermore, executive officers around the world are full of bright ideas, as well as meaning engineers and managers who treat the aspect of correct lubrication and the application of proper tribological techniques, as either unnecessary, too costly, or both.

These same people mistakenly assume that the consequences of friction and wear are “normal” and refuse to take advantage of the huge savings and improved machinery reliability which could be achieved with the proper lubricants, understanding Tribology (the study and application of the principles of friction), and paying more attention to the problems related to friction, and wear.

The word “Tribology” (the study and application of the principles of friction)was introduced in the 1960’s to mean the “science and technology of the wear of interacting surfaces in relative motion and associated subjects and practices”. Tribology (the study and application of the principles of friction) effectively coordinates many technical disciplines, such as chemistry, metallurgy, machine design, lubrication engineering, etc., for solving friction and wear problems.

The main cause of wear in engines and other lubricated systems is abrasion and oil contamination. It is ironic that while engineers and tradesmen are taught how to design, build, or repair equipment, few are taught an understanding of the inter-relationship between friction, wear and lubrication and how to reduce the problems associated with these aspects of equipment operation.

The above brings us to Petron Plus and Petronomics® Products. For almost a quarter of a century, we have been providing Petron Plus and Petronomics products to the agricultural, aviation, aerospace, city/states agencies, food/drug mfg., hospitals, hotels/motels & commercial properties, industrial plants, commercial, mining/quarries & cement plants, automotive manufactures, industrial fleet, motorsports race teams, metalworking facilities, oil companies, pulp & paper mfg., power plants, printing & publishing, recreation operations, steel/metal operations, transportation operations, university & schools, military and government applications around the world.

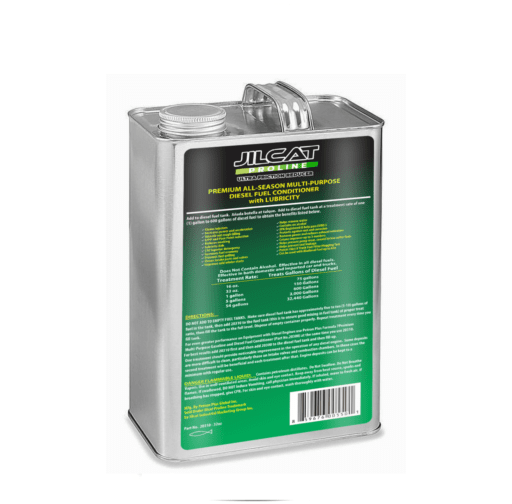

Petronomics® Manufacturing Group, Inc. (PMGI). PMGI manufactures over 305 finished products with 1,320 sku (part numbers) numbers. They range from finished synthetic, non-synthetic and partial synthetic motor oils, ATF’s, automotive gear oils, industrial gear oils, hydraulic fluids, compressor oils, natural gas engine oils, automotive a/c lubes, turbine oils, refrigeration oils, natural gas compressor oils, aerosol products, greases, metalworking fluids, to gasoline additives, diesel fuel additives, industrial cleaning products, and automotive and fleet cooling systems cleaners and corrosion inhibitors & treatments. Some of these products have H-1 and H-2 food grade approval by USDA. PMGI has a product line that meets certain Military Specifications. PMGI also manufactures a line of supplemental products that can be added to existing lubricants.

Petron Plus Formula 7 supplemental technology is not an oil additive, nor a replacement petroleum product, but a Patented new package of high-tech petroleum and synthetic constituents chemically bonded together in a patented new process to form a totally new EP ingredient, (Petron Plus Formula 7 and Petronomics® Formula 7), which may easily be blended in small proportions into virtually any standard lubricant currently available.

The JilCat Proline molecules are very small, 0.1 micron in size (a human hair is 50 microns). If you could imagine for a moment …Solid additives (i.e., PTFE, Teflon® (a registered trademark of DuPont), Moly, Graphite, etc.) are 2 to 10 microns in size. This would be how a beach ball would compare to a golf ball. Petron Plus is much the size of a cold virus, and in that conjunction can’t be stopped.

When Petron Plus/Petronomics is added to any vehicle or heavy duty equipment’s existing lubricant package, (petroleum or synthetic), Petron Plus/Petronomics significantly strengthens the base-lubricant’s overall protective qualities and enhances its existing additive base by providing maximum rust inhibition, anti-oxidation, and the newest, most powerful friction reducing anti-wear agent available.

PETRON PLUS Contains NO TEFLON® or PTFE RESINS, GRAPHITE, MOLYBDENUM DISULFIDE (MOLY), COPPER, LEAD, SILVER or other metals, nor other previously used EP agents, PETRON PLUS DOESN’T Contain CARBON TETRACHLORIDE, 1,1,1, TRICHLOROETHANE, or CHLORINATED PARAFFINS or CHLORINATED SOLVENTS or any other harmful solvents.

Jilcat Proline products protect by impregnating metal at contact and wears points to tremendously reduce friction and wear at those points. The products perform well at any temperature but work best at higher temperatures generated by machinery operation or friction. The penetrating formula does not easily burn, wash, or wear away.

Tests have been run by some of the largest companies around the world, with excellent results. From Europe, Egypt, to China, as well as highly respected independent research and testing laboratory in San Antonio, Texas, regularly conducts competitive performance tests on Petron Plus engineered products. These tests are the most stringent for products of this type, and consistent results demonstrate that Petron Plus engineered products exceed the performance of all competitors and significantly enhances performance characteristics of high-quality base motor oils and gear oils.

Most users realize immediate multiple benefits when JilCat Proline products are introduced into a broad range of machinery, equipment, metalworking, or vehicle applications:

· Helps substantial to increase equipment operating life, with consistent “like new” performance.

· Helps to decrease energy or fuel required for normal equipment operation.

· Helps to increase horsepower and performance output, even under high load, high performance demands.

· Helps to decrease operating temperatures in gear boxes, bearing housing and engines.

· Helps to keep lubricant contamination in suspension, thereby increasing lubricant life.

· Helps increase the ability of base lubricants to prevent rust and corrosion, resist oxidation.

· Helps to significantly reduce maintenance downtime, labor, and parts replacement costs.

· Helps to increase overall efficiency and productivity of operating equipment.

· Helps to increase base lubricant life, thereby decrease drain intervals.

· Helps to increase profitability for firms operating the equipment utilizing JilCat Proline products.

We hope this information helps. Should you have any questions or require specific information about any of our products, please, do not hesitate to call our Product and Service Centers Hotline in Brazil and United States at the addresses shown at our contact page.

Thank you for your consideration regarding Jilcat products, and your obvious concern for quality lubricants.

Jilcat products are “Guaranteed… because we value your investment as much as you do!”